LogPro debarking technologies are custom engineered to geographic location and fiber supply. We design, manufacture, and service our debarking equipment from our state of the art facilities located in Central Arkansas and Central Georgia. Our 30 plus year experience with over 150 operational drum debarker systems around the world makes us a industry leader in debarking drum technology.

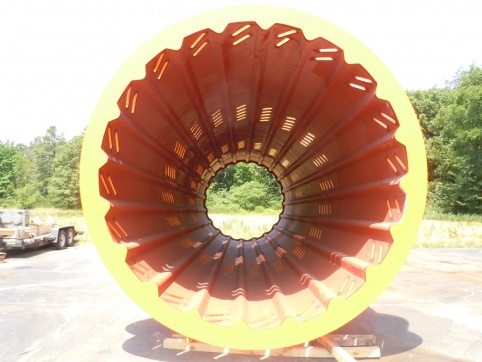

LogPro debarking systems are optimizing woodyard operations throughout the forest products industry with XXHD design, Premium Efficiency electric drives & various lifter arrangements. This flexibility allows for debarking perfection while reducing white wood losses in an easily maintainable power system. Available in (9’-15’) foot diameter sizes to any length from (15’-120’) for the appropriate sized wood, our drums meet the industries highest quality specifications, with up to 1.5 inch shell thickness; 5% – 11% bark slot area; 30,000 lb. rated axle assemblies; plus maintenance and safety features that cost extra on competitor’s drum systems. From biomass and engineered wood products to maximum volume for Pulp & Paper Service Duty, LogPro has a shell design/drum model for your needs.

Rugged LogPro Drum Debarkers are engineered and manufactured to meet the most rigorous standards in the industry. They meet the demands of heavy production schedules, year-in and year-out, with less downtime. This high-production equipment is energy-efficient, easy to maintain, and can dramatically increase throughput to the highest level in the industry. Operation costs are reduced and production rates are increased for a competitive advantage.

Contact us today for more information!

LogPro’s log handling technologies are custom engineered to each specific application. We design, manufacture, and service our log handling equipment from our state of the art facilities located in Central Arkansas and Central Georgia. Our 30 plus year experience makes us the domestic leader in log handling technology. LogPro’s log handling systems are optimizing woodyard operations throughout the forest products industry with XXHD design, Premium Efficiency electric drives & various log handling arrangements. This flexibility allows for reliable log handling while greatly reducing downtime in an easily maintainable & safe unit.

LogPro continues to offer our standard gravity chute infeed design. With over 60 of these systems in production today, this technology has proved to provide a simple and cost effective way to feed a drum debarker. Although not as efficient as our Horizontal Feed conveyors, many customers can start out with this technology and upgrade at a later date when higher production is required.

Contact us today for more information!

Debarker Features

- Conical anti-wedge chute design matches drum diameter for optimal flow

- Extended Infeed Height for safety and performance – Matched Drum Diameter for optimal flow

- Impact areas of chute are fabricated from 1.5”-2” Thick Rolled reinforced steel

- LogPro as a standard lines the high wear area (belly) of the chute with 1” thick replaceable AR 500 wear strips ensuring low maintenance while making it easy to replace the high wear areas.